Reduce your waste disposal and transportation costs with our customizable solids-liquid separation.

The solids-liquid separation process is an effective way to deal with a large volume of sludge or liquid waste with a high solids content. Envirotec’s solids-liquid separation technology is a solution designed to significantly reduce your total volume of waste, by removing the solids from the water or drilling mud.

The solids-liquid separation process is an effective way to deal with a large volume of sludge or liquid waste with a high solids content. Envirotec’s solids-liquid separation technology is a solution designed to significantly reduce your total volume of waste, by removing the solids from the water or drilling mud.

Removal of slurry material. (Dredge, Excavate, Pump, Etc.)

Process slurry through separation system. (Designed for application.)

Stackable solids for haul off and disposal (or reuse).

Produced water for reuse or disposal.

Our 2-step solids-liquid separation leaves you with manageable solids and liquid waste – and an improved waste management experience.

The current methods to manage liquid waste involves hauling it off in vacuum trucks or solidifying it by adding compounds that turn liquid waste into dry waste. Both these traditional methods are costly and do not actually reduce your waste volume while adding to your waste footprint.

Using Envirotec’s solids-liquid separation process, you can…

Envirotec’s mobile systems separate the water from your waste. The water could be reused or discharged economically. Only solids will need to be disposed of, reducing your waste volume significantly. Envirotec’s innovative separation processes reduce your waste volume by up to 50% of the initially slurry volume.

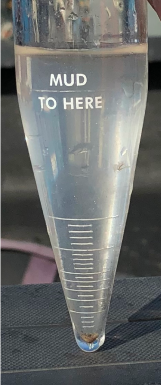

Envirotec’s solids-liquid separation process reduces your waste volume by up to 50%. The image on the left shows the original waste slurry (raw material). The images on the right show the stackable solids and water obtained following the solids-liquid separation process.

Envirotec’s solids-liquid separation process produces stackable solids that will pass the paint-filter test. The paint filter test is an EPA approved test used to determine the presence of liquids in dried solids and is required for acceptance at landfills. In addition to reducing the waste volume, converting the waste from liquid slurry to dry solids generates significant disposal cost savings. Dry solids are much cheaper to dispose of than liquid waste.

Slurry waste needs to be hauled off in vac trucks which are expensive to hire and operate. Converting liquid waste to dry solids generates significant savings. Dry solids can by transported in roll-off bins or dump trucks which is a much cheaper haul off method.

Envirotec’s advanced separation systems are also used in drilling applications. When drilling with bentonite or polymer, Envirotec’s separation equipment will remove fine particles and allow you to control solids content in your drilling fluids. This process gives you the ability to reuse the drilling fluids, instead of having to replenish with fresh water and bentonite or polymer each time. This provides significant cost savings from no longer having to haul off and dispose of used drilling slurry. As a result, this reduces your water and polymer usage demand to mix new mud.

Envirotec’s advanced separation systems boosts your drilling productivity by allowing you to reuse drilling fluids, thereby reducing your water usage demand and the costs associated with disposing of drilling waste.

The components of the Envirotec separation systems are modular, allowing us to scale to meet your processing volume requirements. Envirotec utilizes high-G vibratory shakers, desanders, desilters, custom-built separation tanks, and variable high speed and high-volume specialty centrifuges. Our system is modular, flexible, and efficient, allowing us to design a solution to meet your project’s specific applications

Common applications of our separation systems include:

Envirotec uses a variety of modular equipment to meet your unique waste management and separation needs.

We are committed to helping you reduce your waste volume using state of the art solids-liquids separation processes, saving waste disposal and transportation costs.

For drilling applications, our modular and flexible separation system boosts your drilling productivity by allowing you to reuse drilling fluids reducing your water usage and bentonite/polymer demand, saving you on the disposal costs associated with disposing used drilling fluids.

We are committed to helping you reduce your waste volume using state of the art solids-liquids separation processes, saving waste disposal and transportation costs.

For drilling applications, our modular and flexible separation system boosts your drilling productivity by allowing you to reuse drilling fluids reducing your water usage and bentonite/polymer demand, saving you on the disposal costs associated with disposing used drilling fluids.

Quick Links:

Services:

Connect: